Mech-Ten Mechanical Bolt Tensioning

New Product

The Clarkwood Engineering Mech-Ten Mechanical Bolt Tensioning tool has been developed to provide a method of correctly tensioning studs to give reliable trouble free bolted joints.The Mech-Ten is easy to use, flexible and provides an effective method of tensioning studs wherever it is needed and in virtually any environment.

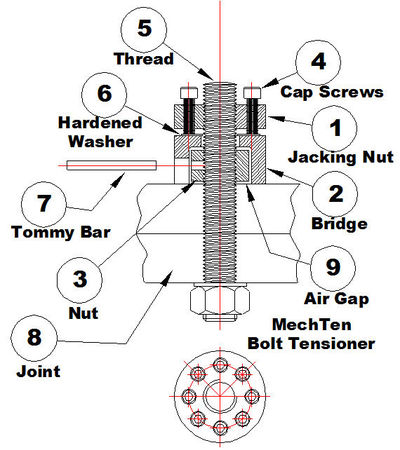

Key to Diagram

- Jacking nut used to stretch and tension stud (5)

- Bridge

- Nut

- Row of cap screws that generate load in stud (5)

- The stud being tensioned

- Hardened washer

- Tommy bar Joint

- Gap created by stretching (tensioning) stud (5)

Features & Benefits

- This method of mechanical bolt tensioning is safe and reliable

- No hydraulics – cost effective on initial outlay

- High quality standard, manufactured from high strength steel for long life and safety

- Protective coated for corrosive resistant

- Can be used by semi-skilled labour – (easy to use)

- Powerful bolted joint with high clamping force

- Low torque requirements - multiple summation of tension from a pitch circle of small sized capscrews (well Proven Method)

- Safe method of assembly (no high pressure hydraulics)

- Tightens stud in pure tension (no torsional strain)

- No thread gallingCompact design

- Protects the environment (no electric power required)

- Quality controlled to ISO 9001: 2008 / ISO 14001:2004

After tensioning the Mechanical Bolt Tensioner (Mech-Ten) can be removed leaving only the Nut Item (3) and Stud Item (5) so the Mech-Ten can be used to tension other studs.

Simple to Use

- Screw Stud (5) into Joint

- Screw Nut (3) onto Stud (5)Fit Bridge (2)

- Fit Hardened Washer (6)

- Screw Jacking Nut onto the Stud (5)

- Select Hand Operated Torque Wrench and set to half the final torque setting

- Sequence Star method of tightening capscrews to uniform bolted joint tightening.

- Tommy Bar (7), Nut (3) to Take up gap

- Set final torque setting and follow the same sequence to apply the tensile tension into Stud (5)

- Tommy Bar (7), Nut (3) to Take up gap

- Reverse sequence of untightening capscrews to remove load

- Remove Jacking Nut (1)

- Remove Bridge (2)