TENSFI load sensors are capable of detecting the varying load that is applied to industrial and engineering fastened joints. They are able to support various fastened joint (e.g. stud, bolted) applications ranging between M20 and M64.

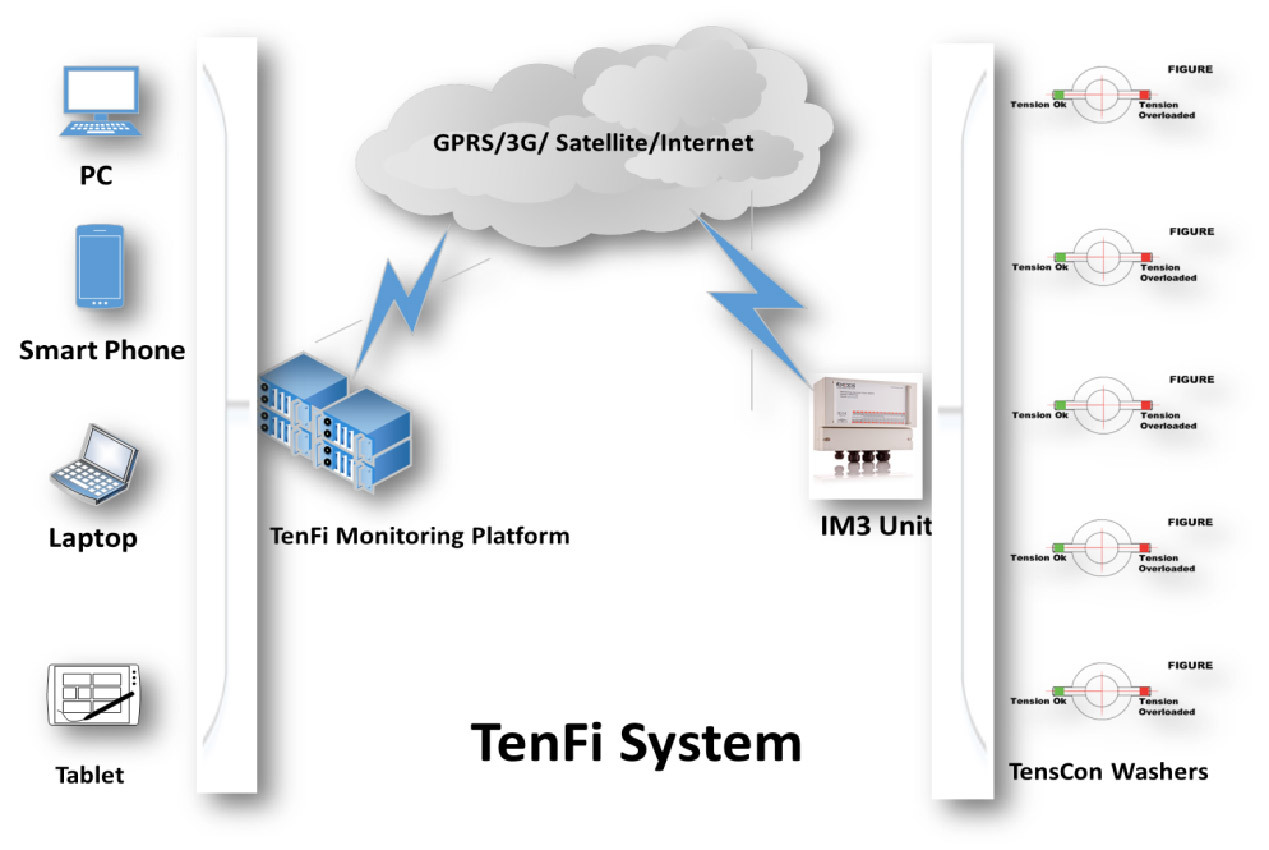

TENSFI Intelligent Washers contain all the necessary components to be able to detect the applied load. The information from the washer can be passed through 4-20mA interface or via Modbus RTU over RS485. Using Modbus allows multiple washers to be connected to the same network, also by introducing a gateway device the information can be passed to the cloud where it can be monitored. Alarms against set points can be setup to notify engineers of any change.

TENSFI Intelligent Washers contain all the necessary components to be able to detect the applied load. The information from the washer can be passed through 4-20mA interface or via Modbus RTU over RS485. Using Modbus allows multiple washers to be connected to the same network, also by introducing a gateway device the information can be passed to the cloud where it can be monitored. Alarms against set points can be setup to notify engineers of any change.

BENEFITS

COST REDUCTION

- More efficient use of maintenance resources

- Significantly reduced installation times

- Lowest total cost of ownership

- Able to work with any existing industry standard bolting mechanism

HEALTH AND SAFETY

- Increased infrastructure reliability

- Improved safety and working environments

- 24x7 Real time notification of infrastructure failure

- Readily accessible audit logs to support and demonstrate regulatory compliance

REDUCED OPERATIONAL RISK

- Can be used in a wide variety of locations and operational environments

- Improved operational risk assessment in emergency situations

- Significantly reduced installation and system complexity

- Removal of human error associated with the bolt tightening process

- More accurate tensioning of bolt loads

- Instant and accurate recording of all maintenance activity